sales@loadcellsensor.com

sales@loadcellsensor.com

Understanding the Science Behind Compression Load Cells: Optimizing Precision in Measurements

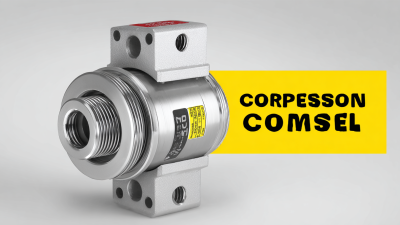

In the realm of industrial measurement technology, the importance of accuracy cannot be overstated. Compression load cells, pivotal components in various applications, have shown significant advancements in precision engineering, with recent reports indicating that the global load cell market is projected to reach $1.9 billion by 2026, reflecting a compound annual growth rate (CAGR) of 4.5%. These sensors are integral in industries ranging from manufacturing to aerospace, where the need for precise weight and force measurements is critical for operational efficiency and safety. Understanding the science behind compression load cells is crucial for optimizing their performance and ensuring accuracy in measurements. As manufacturers continue to innovate, leveraging advanced materials and technologies, the potential for improved precision and reliability in force measurement will only increase, making it essential for practitioners to stay abreast of these developments.

The Fundamental Principles of Compression Load Cells Explained

Compression load cells are essential devices used to measure force or weight through the application of compression. At their core, these load cells operate on fundamental principles of physics, particularly the concept of strain. When a force is applied to the load cell, it deforms slightly, and this deformation generates a measurable electrical signal. The relationship between the amount of force and the resulting deformation is usually linear, making it straightforward to calibrate and optimize for accurate measurements.

One key element that contributes to the precision of compression load cells is the material selection for the sensing element. Commonly, high-strength materials like aluminum or stainless steel are used due to their ability to maintain structural integrity under varying loads. Additionally, the design of the load cell itself plays a crucial role. Properly designed load cells will minimize factors such as hysteresis and temperature effects, which can lead to measurement errors.

By understanding these fundamental principles, engineers can better select and implement compression load cells to enhance accuracy in various applications, from industrial weighing scales to sophisticated scientific instruments.

Key Factors Influencing Measurement Precision in Compression Load Cells

Compression load cells are essential components in various industrial applications, relied upon for their accuracy in force and weight measurements. However, several key factors can significantly influence the precision of these measurements. One primary factor is the alignment of the load cell during installation. Misalignment can lead to off-axis forces, resulting in erroneous readings. Ensuring proper installation and alignment is crucial to maintain the integrity of the data captured by the load cell.

Another critical element affecting measurement precision is temperature variability. Compression load cells are sensitive to temperature fluctuations, which can induce thermal expansion or contraction of the materials involved, thereby skewing results. Utilizing load cells with temperature compensation features can mitigate this issue, allowing for more reliable measurements across varying environmental conditions.

Additionally, the material quality and design of the load cell itself play vital roles in achieving accurate measurements, with high-quality materials and well-engineered designs minimizing hysteresis and improving overall response times.

Common Applications of Compression Load Cells in Various Industries

Compression load cells are vital instruments widely used across various industries to ensure accurate weight and force measurements. In the construction industry, for instance, these devices are integral in monitoring the loads on structural components, helping engineers validate designs and avoid structural failures. Their ability to provide precise measurements allows for safe construction practices and compliance with regulatory standards.

In manufacturing, compression load cells play a crucial role in quality control processes. They are employed in packaging systems to ensure that products meet specified weight requirements. This not only helps maintain consistency but also minimizes waste and maximizes efficiency. Additionally, load cells are commonly utilized in the automotive sector, where they assist in testing and verifying the performance of various components under load, ensuring vehicles meet safety and durability standards. The versatility of compression load cells across these applications highlights their importance in promoting safety and efficiency in everyday operations.

Technological Advancements Enhancing Compression Load Cell Accuracy

With the increasing demand for precision in various industrial applications, compression load cells have witnessed significant technological advancements aimed at enhancing their accuracy. According to a report by the International Society of Automation, modern load cells now achieve an accuracy of up to ±0.01% of the full scale, a notable improvement over older models which typically ranged around ±0.1%. These advancements are driven by innovations in materials and digital signal processing that reduce noise and increase measurement fidelity.

Furthermore, the integration of smart technology into compression load cells has transformed how data is collected and analyzed. Advanced load cells equipped with IoT capabilities enable real-time monitoring and data logging, ensuring that measurements can be instantly verified and adjusted. A recent market analysis published in the Journal of Measurement Science indicates that the adoption of such technologies has resulted in a 30% improvement in operational efficiencies across various sectors, including manufacturing and aerospace. As industries continue to demand higher precision, ongoing innovations in compression load cells will undoubtedly play a critical role in the quest for accuracy.

Understanding the Science Behind Compression Load Cells: Optimizing Precision in Measurements - Technological Advancements Enhancing Compression Load Cell Accuracy

| Parameter | Standard Value | Current Technology | Advancements | Notes |

|---|---|---|---|---|

| Accuracy | ±0.1% | ±0.05% | Digital Signal Processing | Enhanced accuracy through advanced filtering techniques. |

| Capacity | 0-1000 kg | 0-5000 kg | Material Improvements | Stronger materials enable higher load capacities. |

| Temperature Range | -20°C to 60°C | -40°C to 80°C | Thermal Compensation | Improved thermal management increases operational range. |

| Response Time | 20 ms | 5 ms | Innovative Sensor Design | Faster response time increases measurement efficiency. |

| Output Signal | 4-20 mA | Digital Output (RS-485) | Smart Sensors | Digital output enhances data transmission reliability. |

Challenges and Solutions in Achieving Optimal Load Cell Performance

Compression load cells are essential for various industrial applications, providing precise measurements of force and weight. However, achieving optimal performance in these devices comes with its own set of challenges. Environmental factors such as temperature fluctuations, humidity, and vibrations can significantly affect the accuracy of load cell readings. Moreover, the alignment and installation of the load cell itself play a crucial role in ensuring reliability and consistency in measurements.

Compression load cells are essential for various industrial applications, providing precise measurements of force and weight. However, achieving optimal performance in these devices comes with its own set of challenges. Environmental factors such as temperature fluctuations, humidity, and vibrations can significantly affect the accuracy of load cell readings. Moreover, the alignment and installation of the load cell itself play a crucial role in ensuring reliability and consistency in measurements.

To overcome these challenges, it is vital to implement certain best practices. Firstly, ensure proper calibration of the load cells before use, regularly checking their accuracy against known standards. Secondly, consider environmental controls; for instance, installing load cells in temperature-regulated areas can mitigate the effects of heat and cold. Lastly, using protective housings can shield load cells from excessive moisture and vibrations.

Tips: Regular maintenance and inspection are critical for optimal load cell performance. Ensure load cells are mounted correctly and periodically check for any signs of wear or misalignment. Additionally, employing signal conditioning equipment can help in filtering out noise, enhancing measurement precision. By addressing these challenges and integrating effective solutions, the performance of compression load cells can be significantly optimized.

Related Posts

-

Rise of Chinese Manufacturing in Micro Load Cells Amidst US China Tariff Challenges

-

Top Strategies for Selecting the Best 5kg Load Cell for Your Business Needs

-

Understanding Import Export Certifications for Best Thin Load Cells with a Comprehensive Tutorial Guide

-

Discovering the Best Compression Load Cells: A Global Buyer’s Guide for Performance and Reliability

-

Exploring Alternative Load Cell Solutions for Optimizing Tensile and Compressive Testing

-

Unlocking Efficiency: Key Advantages of Utilizing Compression Load Cells in Industrial Applications