sales@loadcellsensor.com

sales@loadcellsensor.com

7 Unique Benefits of Compression Type Load Cells for Modern Industries

In the rapidly evolving landscape of modern industries, the adoption of advanced measurement technologies has become critical for ensuring efficiency and accuracy in operations. One such technology, the Compression Type Load Cell, is gaining recognition for its unique advantages in a variety of applications. According to a recent report by MarketsandMarkets, the global load cell market is projected to grow from USD 3.07 billion in 2020 to USD 4.55 billion by 2025, driven by the increasing demand for precision measurement in sectors such as manufacturing and construction. Compression Type Load Cells stand out due to their ability to accurately measure static and dynamic loads, withstand harsh environments, and provide reliable data critical for quality control. As industries increasingly focus on automation and IoT integration, understanding the unique benefits of Compression Type Load Cells becomes essential for enhancing operational effectiveness and reducing costs.

The Evolution of Compression Type Load Cells in Industrial Applications

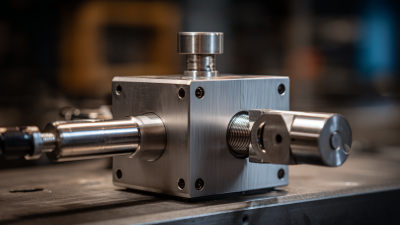

The evolution of compression type load cells has revolutionized industrial applications, marking a significant shift in how weight measurement is approached across various sectors. Initially designed for simple weighing tasks, these innovative devices have adapted remarkably to the demands of modern industries, embracing advanced technologies and materials that enhance their performance and reliability. By integrating precision engineering with smart technology, compression load cells now offer unparalleled accuracy and durability, making them indispensable in settings ranging from manufacturing to aerospace.

One of the most notable advancements in compression type load cells is their ability to withstand extreme environmental conditions, ensuring consistent measurement even in harsh settings. This resilience is due to advancements in materials science, which allow these devices to function effectively under high pressures and varying temperatures. Additionally, the integration of digital technology and wireless communication has enabled real-time data transmission, giving industries immediate access to critical information. As businesses continue to seek efficiency and precision, the evolution of compression type load cells is set to play a vital role in driving innovation and enhancing productivity across the board.

Enhanced Accuracy: How Compression Load Cells Improve Measurement Precision

Compression load cells are essential tools for enhancing accuracy in measurement precision across various modern industries. Unlike traditional load cells, compression load cells provide a more direct and reliable means of assessing force and weight. The recent advancements in sensor technology, particularly in electrochemomechanics and force sensing, emphasize the need for precise measurements to improve system efficiency and performance. For instance, a study on all-solid-state batteries highlighted the critical role of stack pressure regulation in achieving optimal performance, demonstrating that accurate measurements can significantly influence the lifespan and effectiveness of energy storage systems.

Tips: When selecting compression load cells, consider their linearity and hysteresis specifications to ensure minimal calibration errors. Implementing regular calibration procedures is crucial for maintaining measurement accuracy, especially in dynamic environments where precision is paramount.

Furthermore, innovative applications such as robotic-assisted precision machining rely heavily on advanced sensors and load cells. Recent integration of virtual prototyping techniques in sensor design encourages the development of more sophisticated solutions that yield precise feedback during manufacturing processes. As industries increasingly adopt digital solutions, the demand for high-performance, accurate measurement tools like compression load cells will only continue to rise.

7 Unique Benefits of Compression Type Load Cells for Modern Industries

This chart illustrates the various benefits of compression load cells regarding measurement precision in modern industries.

Cost Efficiency: The Financial Advantages of Using Compression Load Cells

Compression load cells are increasingly becoming a preferred choice in modern industries due to their cost efficiency and reliability. According to a report by MarketsandMarkets, the load cell market is expected to reach $1.5 billion by 2025, mainly driven by the rising need for accurate measurement and monitoring in diverse applications such as automotive, aerospace, and manufacturing. By significantly reducing operational costs, compression load cells allow companies to streamline their processes, maximize productivity, and ultimately enhance their bottom line.

When considering the financial advantages, compression load cells excel in minimizing maintenance expenses. Unlike traditional load measuring devices that may require frequent recalibration and repairs, compression load cells often have a longer lifespan and require less upkeep. This feature translates to substantial savings over time. TIPS: Regularly monitoring the performance of your load cells can help you detect early signs of wear and prevent costly failures.

Furthermore, the initial investment in compression load cells can pay off rapidly, as they can provide precise measurements that lead to better quality control and reduced waste. Research from the Institute of Electrical and Electronics Engineers indicates that companies leveraging advanced load cell technologies can achieve a 20% reduction in manufacturing defects. TIPS: Investing in quality load cells and proper training for your team can yield long-term financial benefits and improve operational efficiency.

Durability and Longevity: The Benefits of Load Cells in Harsh Environments

In modern industries, the application of compression type load cells is gaining traction, particularly for their remarkable durability and longevity in harsh environments. These sensors are designed to withstand extreme conditions, including temperature fluctuations, moisture, and corrosive substances, which are common in sectors like construction, manufacturing, and aerospace. According to a report by Research and Markets, the global load cell market is projected to grow at a CAGR of 4.5% through 2025, highlighting the increasing reliance on these robust measurement tools.

The advanced materials and technology used in compression load cells significantly contribute to their lifecycle and reliability. For instance, many models feature stainless steel housings that resist rust and degradation, making them suitable for outdoor applications or areas with high exposure to chemicals. A study from the National Institute of Standards and Technology indicates that load cells can exhibit a lifespan of over 10 years even when operating in challenging environments, drastically reducing maintenance costs and downtime for businesses. This resilience not only enhances operational efficiency but also ensures accurate weight measurement, a critical component for inventory management and quality control in various industries.

7 Unique Benefits of Compression Type Load Cells for Modern Industries - Durability and Longevity

| Benefit | Description | Applications |

|---|---|---|

| High Accuracy | Provides precise measurements crucial for quality control. | Manufacturing, Aerospace |

| Durability | Resistant to harsh conditions, ensuring long-term performance. | Mining, Construction |

| Low Maintenance | Requires minimal upkeep, reducing operational costs. | Logistics, Heavy Equipment |

| Wide Measurement Range | Can handle various loads, from small to large. | Food Industry, Chemical Processing |

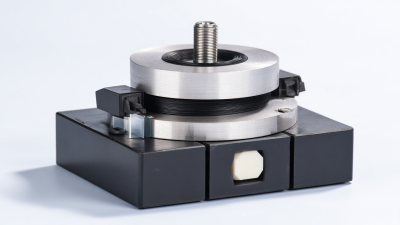

| Compact Design | Space-saving, easy to integrate into existing systems. | Automotive, Robotics |

| Temperature Stability | Maintains performance in extreme temperatures. | Oil & Gas, Power Generation |

| Real-time Monitoring | Allows instantaneous tracking of load changes, improving safety. | Smart Manufacturing, Warehousing |

Data Integration: The Role of Compression Load Cells in Industry 4.0

In the era of Industry 4.0, data integration has become a cornerstone for achieving operational efficiency and innovation. Compression type load cells play a pivotal role in this transformation, providing accurate weight measurements that are essential for real-time data analytics. These load cells facilitate the seamless connectivity of various industrial processes, enabling the collection of vital information that can be analyzed for smarter decision-making. By integrating compression load cells into production lines, industries can monitor material usage, improve supply chain management, and optimize resource allocation.

In the era of Industry 4.0, data integration has become a cornerstone for achieving operational efficiency and innovation. Compression type load cells play a pivotal role in this transformation, providing accurate weight measurements that are essential for real-time data analytics. These load cells facilitate the seamless connectivity of various industrial processes, enabling the collection of vital information that can be analyzed for smarter decision-making. By integrating compression load cells into production lines, industries can monitor material usage, improve supply chain management, and optimize resource allocation.

Moreover, the precision and reliability of compression load cells enhance data integrity, ensuring that the information fed into industry systems is both accurate and trustworthy. This reliability allows for advanced predictive analytics, helping companies to forecast maintenance needs and reduce downtime. With continuous monitoring and data-driven insights, businesses can adapt swiftly to changing market demands and streamline their operations, making compression load cells an indispensable component of modern industrial infrastructures shaping the future of manufacturing.

Related Posts

-

Common Issues Faced When Using Best Small Load Cells

-

Exploring Innovative Alternatives to the Best Tension Compression Load Cell for Global Buyers

-

The Ultimate Guide to Sourcing High-Quality Suppliers for Best Button Type Load Cells

-

Global Sourcing Revolution: How China's Best Thin Load Cells Set the Standard for Quality and Reliability

-

Ultimate Checklist for Choosing the Best Compression Type Load Cell for Your Business Needs

-

The Ultimate Guide to Choosing the Best Load Cell for Your Needs