sales@loadcellsensor.com

sales@loadcellsensor.com

Enhancing User Experience: The After-Sales Service and Maintenance Cost Benefits of the Best Load Cell Sensor

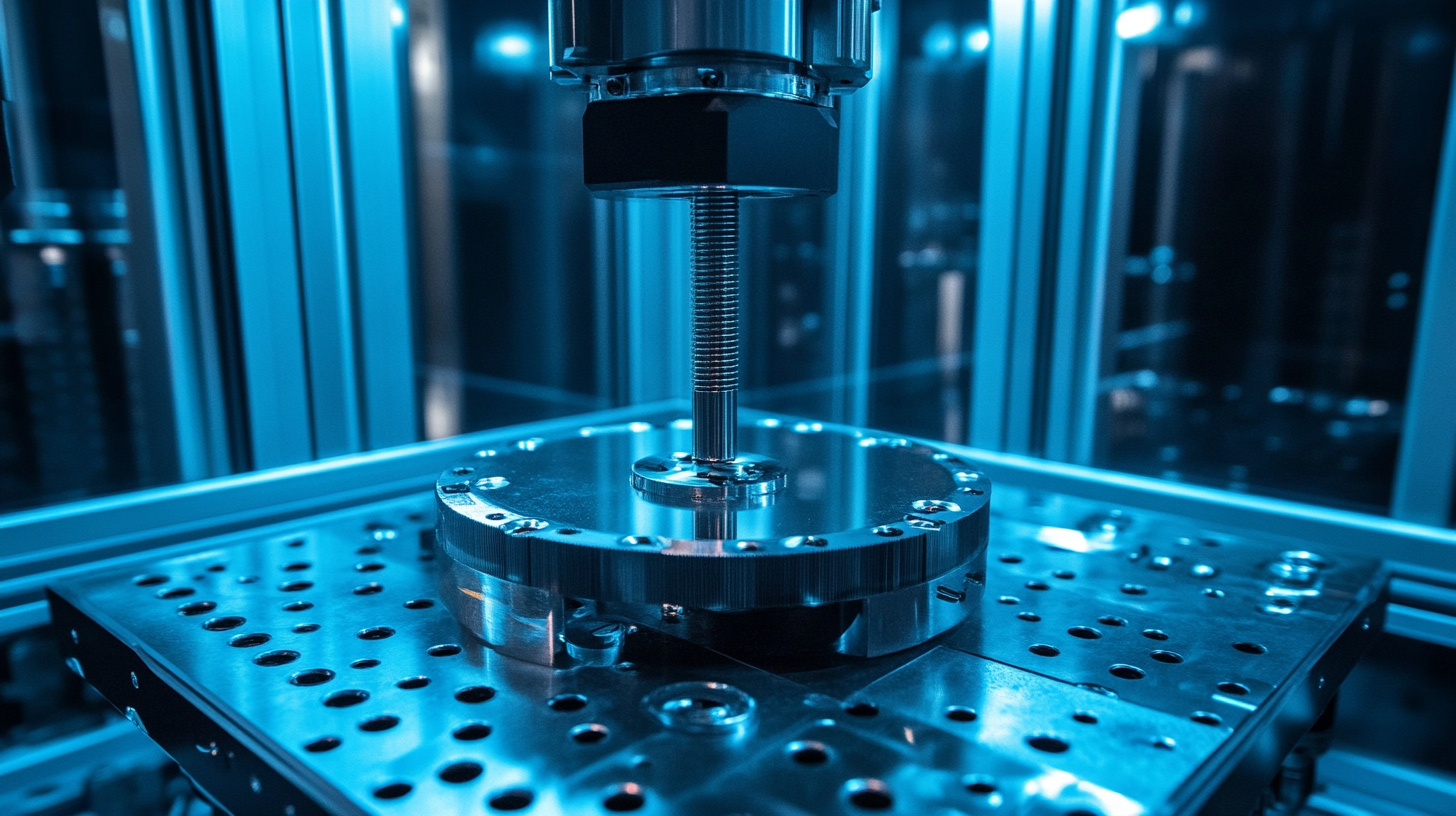

In the world of industrial automation and precision measurement, the Load Cell Sensor plays a pivotal role in enhancing operational efficiency and user experience. According to a report by Markets and Markets, the global load cell market is projected to reach USD 3.4 billion by 2025, growing at a CAGR of 5.5% from 2020. This growth is largely driven by the increasing need for accurate weight measurement and process control across various industries, including food and beverage, pharmaceuticals, and logistics. Moreover, effective after-sales service and maintenance can significantly reduce operational costs and downtime, further underscoring the importance of selecting the best load cell sensor. In this blog, we will explore how optimized after-sales support can enhance user experience and lower maintenance costs, thereby solidifying the Load Cell Sensor as a crucial component in modern industrial applications.

Understanding Load Cell Sensors: Key Features and Benefits

Load cell sensors play a pivotal role in various industries by accurately measuring weight and force, which ultimately enhances user experience. Understanding the key features of these sensors is essential to appreciate their benefits. Precision is one of the primary attributes, as load cells offer unparalleled accuracy in measurements. This ensures that businesses can rely on the data for critical decision-making processes, further reducing potential errors and associated costs.

Another significant aspect of load cell sensors is their robustness and durability. Constructed to withstand harsh conditions, they are designed for longevity, minimizing maintenance requirements. This reliability translates into lower after-sales service and maintenance costs, allowing businesses to focus on core operations rather than sensor upkeep. The integration of load cell sensors with modern technologies, such as IoT devices, further enhances their functionality by enabling real-time data monitoring and analysis, paving the way for more efficient processes and increased productivity.

The Importance of After-Sales Service in Load Cell Sensor Performance

When it comes to load cell sensors, after-sales service plays a crucial role in ensuring optimal performance and longevity. Customers who invest in high-quality load cells often overlook the significance of support provided post-purchase. A responsive after-sales service can address potential issues before they escalate, ensuring that the sensors operate at peak efficiency. Regular maintenance, calibration, and troubleshooting from skilled technicians not only enhance performance but also extend the lifespan of load cell sensors.

Moreover, the investment in after-sales service is economically beneficial. When businesses ensure their load cell sensors are maintained properly, they experience fewer disruptions in operations. This, in turn, translates to reduced downtime and lower overall maintenance costs. By cultivating a strong relationship with manufacturers that prioritize customer service, companies can secure a steady supply of necessary parts and updates, leading to improved reliability and accuracy in measurements. Ultimately, the right after-sales support can significantly influence the effectiveness and cost-effectiveness of using load cell sensors in various applications.

Enhancing User Experience: After-Sales Service Benefits of Load Cell Sensors

This chart illustrates the maintenance cost benefits and satisfaction levels related to after-sales services for load cell sensors. As shown, improved after-sales services positively impact user satisfaction and reduce overall maintenance costs.

Cost-Effective Maintenance Tips for Load Cell Sensors

When it comes to load cell sensors, effective maintenance plays a crucial role in ensuring their accuracy and longevity. According to a recent industry report by the International Society of Automation, improper maintenance can result in a 30% reduction in sensor lifespan, leading to increased operational costs and unnecessary downtime. To avoid such pitfalls, implementing a proactive maintenance schedule is essential. Regular calibration and inspection can help detect potential issues early, minimizing repair costs and maintaining optimal performance.

Cost-effective maintenance tips for load cell sensors include ensuring proper installation conditions, such as avoiding excessive vibration and temperature fluctuations. Moreover, lubricating moving parts and regularly cleaning the sensor to prevent dust accumulation can significantly enhance performance. The same industry report indicates that organizations that adopt these preventive measures can save up to 25% on repair costs annually.

By prioritizing maintenance and adhering to best practices, businesses not only enhance the user experience but also achieve substantial financial benefits, making load cell sensors a wise investment in the long run.

Enhancing Efficiency: Optimizing User Experience with Load Cells

Load cells play a crucial role in enhancing operational efficiency across various industries by providing accurate weight measurements. According to the latest report from MarketsandMarkets, the global load cell market is projected to reach $2.7 billion by 2026, fueled by the growing demand for precise measurement in automation processes. This rise in adoption underscores the importance of optimizing user experience, as load cells facilitate not only weight detection but also improve inventory management and production workflow.

Moreover, advanced load cell technologies, such as digital load cells, offer real-time data analytics and connectivity, significantly reducing maintenance costs and downtime. A study by Technavio highlights that companies utilizing smart load cells can increase productivity by up to 15% while also cutting down on after-sales service expenses. By integrating load cells into operational frameworks, businesses can provide a seamless user experience, ensuring reliable performance and cost savings, ultimately leading to improved customer satisfaction and loyalty.

Enhancing User Experience: The After-Sales Service and Maintenance Cost Benefits of the Best Load Cell Sensor

| Load Cell Type | After-Sales Support (Years) | Maintenance Cost per Year (USD) | Efficiency Rating (%) | User Satisfaction Score (Out of 10) |

|---|---|---|---|---|

| Digital Load Cell | 5 | 200 | 95 | 9.0 |

| Load Cell with Integrated Amplifier | 4 | 150 | 92 | 8.5 |

| S Load Cell | 6 | 180 | 90 | 8.0 |

| Miniature Load Cell | 3 | 250 | 88 | 7.5 |

| Compression Load Cell | 7 | 220 | 94 | 9.2 |

Comparing the Best Load Cell Sensors for Cost Savings and Reliability

When selecting load cell sensors, both cost savings and reliability are critical factors that influence the overall user experience. Recent industry reports indicate that load cell sensors account for up to 30% of total operational costs in weighing applications. Therefore, investing in high-quality sensors with durable after-sales service can significantly reduce long-term expenses. A survey conducted by the International Society of Automation shows that organizations that prioritize reliable load cell sensors save an average of 20% on maintenance costs over a 5-year period compared to those that settle for cheaper alternatives.

Furthermore, performance reliability is crucial in industrial applications. According to a report from the Materials Testing Institute, sensors with a proven track record of reliability can lower product failure rates by nearly 15%. This decrease not only minimizes downtime but also enhances operational efficiency, ultimately leading to increased profits. With a variety of load cell sensors available in the market, making an informed choice based on empirical data can lead to substantial cost savings and bolster the reliability of operations. Investing in the best load cell sensors ensures that businesses not only meet their immediate needs but also build a sustainable foundation for future growth.