sales@loadcellsensor.com

sales@loadcellsensor.com

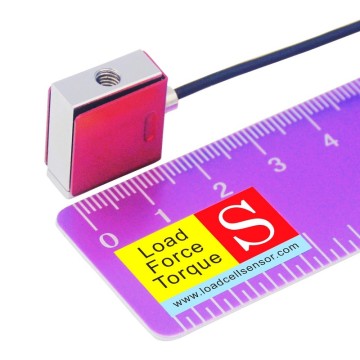

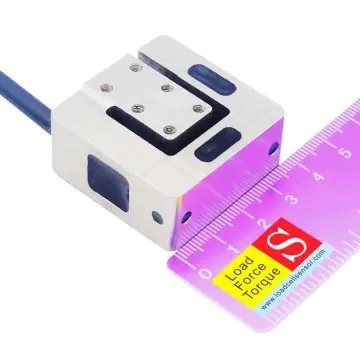

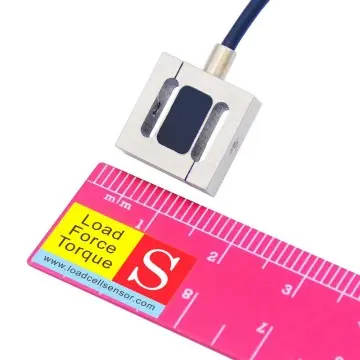

Customizable low profile hollow reaction torque transducer

The hollow design of the RTT02 torque transducer makes it easy to install between components such as motors, switches, or shafts and their mounting plates. The rotating axis passes through the central thru-hole, enabling the sensor to measure the reaction moment of the shaft without being affected by rotational speed. This design ensures that torque is accurately monitored regardless of how fast the shaft rotates.

One of the significant advantages of reaction torque transducers like the RTT02 is that they have no moving parts, making them virtually maintenance-free. This results in a cost-effective solution compared to traditional rotary torque sensors, especially when steady-state measurements are adequate for the application. This robustness makes the RTT02 ideal for environments that require consistent and long-term torque monitoring.

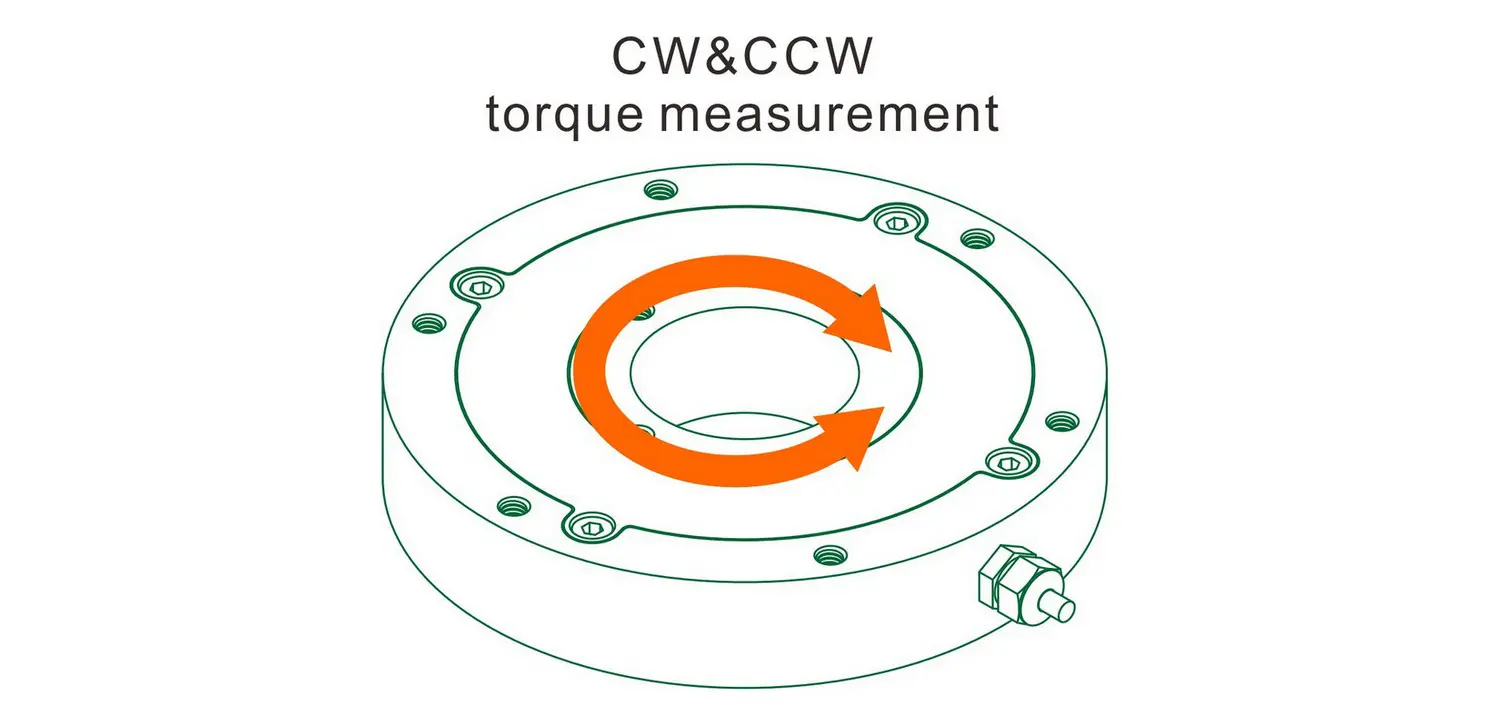

The RTT02 stationary torque meter is calibrated for use in both clockwise and anticlockwise directions, adding to its versatility. Typical applications include fluid viscosity measurement, which requires precise torque readings for accurate fluid dynamics analysis; torsional test machines for material strength testing; rotary actuator testing to ensure proper performance; and process control equipment where continuous torque feedback is essential for system stability.

In addition to standard products, we offer custom modifications of the RTT02 or fully tailored designs to meet specific client requirements, ensuring that our torque sensors are adaptable to specialized industrial needs.