sales@loadcellsensor.com

sales@loadcellsensor.com

Flange Type 3-Axis Force Sensor 5kN 10kN 20kN 30kN 50kN 100kN

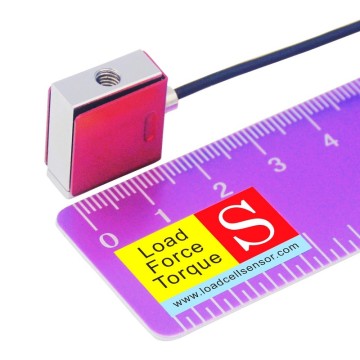

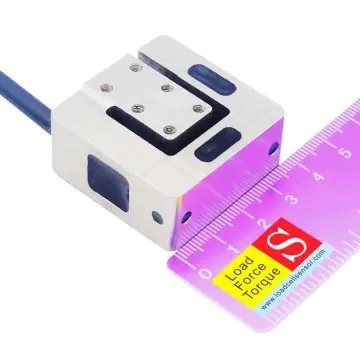

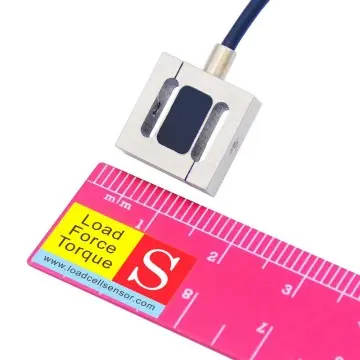

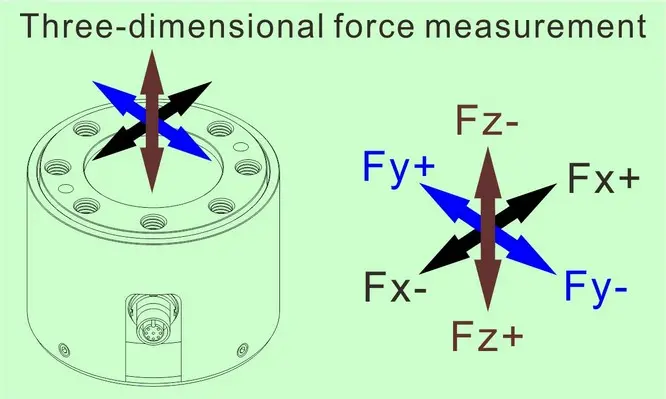

The LCM3D 3-axis load cell is a high-capacity multi-directional force sensor designed for precise force measurement along three mutually perpendicular axes: X, Y, and Z. Utilizing proven strain gauge technology, this load cell offers accurate and reliable measurement in demanding industrial and research environments. The LCM3D features a rugged flange-to-flange construction, which ensures secure mounting, high structural rigidity, and long-term stability under heavy loads. Engineered to capture forces in complex systems, it is available in various sizes and rated capacities to meet diverse application requirements.

One of the unique aspects of the LCM3D is its asymmetrical force range design. The Z-axis is intentionally rated to handle higher loads—three times greater than the X and Y axes—addressing the fact that axial forces in many real-world applications tend to exceed lateral loads. The standard capacity range for the X/Y axes is 5kN to 100kN, while the Z-axis spans 15kN to 300kN. This configuration provides a well-balanced solution for scenarios involving combined forces from multiple directions without sacrificing sensitivity or accuracy.

Constructed from high-strength materials such as stainless steel, the LCM3D is suitable for both static and dynamic force monitoring. It delivers high accuracy, low non-linearity, and excellent repeatability, making it an ideal tool for engineers, researchers, and automation professionals. The sensor is equipped to support real-time multi-directional force feedback in complex testing environments.

Typical applications of multi-axis force sensor LCM3D:

- Structural Load Monitoring

In civil and structural engineering, the LCM3D 3D load cell is used to measure the distribution and magnitude of forces acting on buildings, bridges, support beams, and other large-scale infrastructures. Its ability to detect forces in three axes simultaneously helps engineers analyze stress interactions and ensure structural integrity under various load conditions, including wind, seismic activity, and operational strain.

- Aerospace Component Testing

The aerospace industry demands high-precision data for component testing under multi-directional forces. LCM3D three-component force sensor can be employed in structural validation of aircraft wings, fuselage sections, and landing gear to evaluate performance under simulated flight conditions. The high Z-axis capacity makes it particularly suited for testing components subjected to high axial loads while capturing secondary lateral forces for a complete picture of stress behavior.

- Material Deformation Analysis

In materials science, understanding how materials deform under complex loading conditions is critical. The LCM3D triaxial load cell enables researchers to capture force vectors in three dimensions, helping them determine mechanical properties such as stiffness, yield strength, and fracture behavior. Its accuracy and dynamic response make it ideal for real-time stress-strain analysis during compression, bending, or torsion tests.

- Press-Fit Assembly Force Monitoring

In automated manufacturing, especially in automotive and electronics assembly, monitoring press-fit forces ensures consistent quality and prevents part damage. The LCM3D 3-axis force sensor allows manufacturers to monitor axial pressing forces along with side forces that may indicate misalignment or part interference. This helps in maintaining process control and improving the longevity of both machinery and products.

- Biomechanical Joint Load Simulation

In medical research and biomechanics, simulating joint loads under realistic conditions is essential for developing prosthetics, orthopedic implants, and rehabilitation devices. The LCM3D enables precise measurement of forces acting on artificial joints or limb models, offering insights into movement dynamics and stress distribution. Its compact form factor and multi-axis capability make it suitable for integration into complex test rigs.

- Heavy-Duty Fatigue Testing Systems

Fatigue testing of components such as drive shafts, gearboxes, and heavy machinery parts requires accurate measurement of forces over millions of load cycles. The LCM3D multi-axis load cell is capable of withstanding long-term use in fatigue test benches, providing high-resolution data on force direction and magnitude throughout the test duration. This helps identify failure points and improve material and structural design.

In addition to its standard models, LCS Tech Co., Limited offers custom design services for the LCM3D, including modifications to rated capacities, physical dimensions, mounting configurations, and output specifications to suit specific application needs. Whether for advanced research or industrial automation, the LCM3D series provide a reliable and flexible solution for three-dimensional force measurement.