sales@loadcellsensor.com

sales@loadcellsensor.com

Hollow flange type reaction torque load cell 0-1000Nm

The RTT08 Flange-to-Flange Reaction Torque Sensor is a state-of-the-art measurement solution engineered to deliver precision in both static and dynamic torque applications. Leveraging advanced strain gauge technology, it generates an mV/V output signal directly proportional to the applied torque, ensuring high accuracy across its extensive capacity range. Designed for versatility, the RTT08 adheres to Newton's third law of motion, capturing reaction forces to measure torque without direct contact with rotating components—making it indispensable for industries demanding reliability in harsh or high-cycle environments.

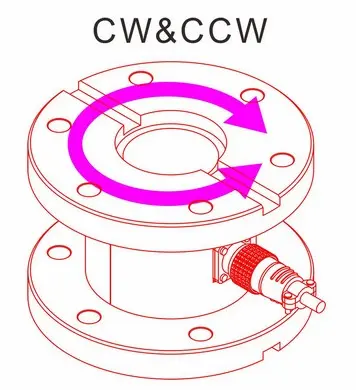

Available in eight capacities—20Nm, 50Nm, 100Nm, 200Nm, 300Nm, 500Nm, 700Nm, and 1000Nm—the RTT08 accommodates diverse torque measurement needs, from delicate actuator testing to heavy-duty industrial processes. Its bidirectional capability allows torque measurement in both clockwise and counterclockwise directions, ensuring adaptability for complex machinery or reversible systems. Each unit undergoes rigorous in-house calibration, accompanied by a certification to guarantee traceable accuracy, compliance with international standards, and peace of mind for quality-focused users.

The RTT08's flange-to-flange configuration and hollow thru-hole design set it apart. The flanges enable robust, bolt-on installation between driven and driving components, minimizing alignment issues and mechanical stress. The central thru-hole permits a rotating shaft to pass through the sensor uninterrupted, facilitating real-time torque measurement in dynamic systems without disrupting operation. This design is particularly advantageous in automotive drivetrains, packaging machinery, or robotics, where continuous rotation is critical. Constructed from high-strength stainless steel, the sensor withstands extreme loads, vibrations, and temperature fluctuations, ensuring longevity in demanding settings like foundries or offshore equipment.

The RTT08 excels in scenarios requiring precise torque control:

-

Automotive Braking Systems: Validates brake caliper torque to ensure safety and compliance with regulatory standards.

-

Packaging Machinery: Monitors sealing torque on pharmaceutical blister packs, preventing under/over-tightening that could compromise product integrity.

-

Actuator Performance Testing: Measures torque output in robotic actuators for precision in automated assembly lines.

-

Assembly Line Machines: Ensures consistent screwdriving torque in electronics manufacturing, reducing defect rates.

-

Material Testing: Evaluates torsional resilience of composites or metals in R&D labs, aiding material innovation.

While optimized for static torque (e.g., bench testing of bolts), the RTT08's dynamic torque measurement capability shines in rotating systems. By capturing reaction forces from rotating shafts—such as in conveyor belt motors or wind turbine gearboxes—it eliminates the need for slip rings or wireless telemetry, reducing maintenance and complexity. This makes it ideal for long-term installations where reliability is paramount.

Understanding that standard solutions rarely fit all, the RTT08 stationary torque load cell can be tailored to niche requirements. Custom flange diameters, alternative thread patterns (e.g., UNF, metric fine), or specialized output signals (4-20mA, RS485) are available. For corrosive environments, optional coatings like nickel plating or epoxy sealing enhance durability. OEMs benefit from bespoke mechanical interfaces or integration with IoT platforms for predictive maintenance analytics.