sales@loadcellsensor.com

sales@loadcellsensor.com

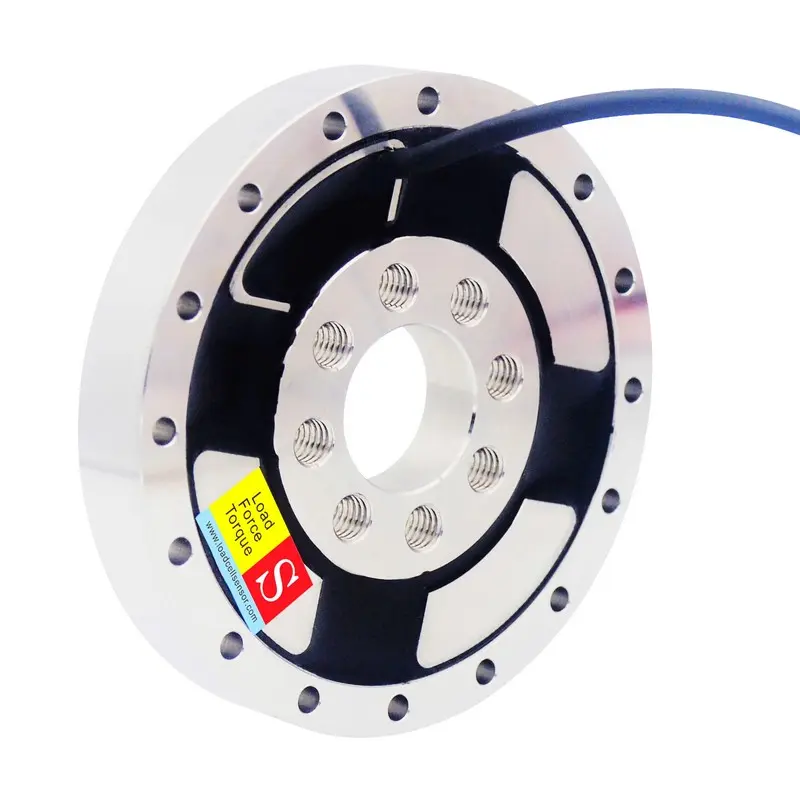

Low profile thru hole reaction torque load cell

The RTT12 Low-Profile Robot Joint Torque Sensor is a reaction-type torque transducer engineered to measure torsional forces between two flanges with exceptional precision. Built with strain gauge technology, it delivers reliable static torque measurement in both clockwise and counterclockwise directions, with four capacity options—20Nm, 50Nm, 100Nm, and 200Nm—to accommodate diverse industrial demands. Beyond static applications, the RTT12 uniquely measures rotating torque by leveraging Newton's third law: capturing the reaction moment generated by a rotating shaft, independent of its speed. This eliminates the need for direct contact with moving parts, ensuring accuracy even in high-speed or dynamic environments.

A standout feature of the RTT12 Reaction Torque Cell is its compact, hollow-through design. The central thru-hole allows a rotating shaft to pass seamlessly through the sensor, simplifying integration into robotic joints or automated systems where space constraints are critical. This design not only streamlines installation but also eliminates the wear-and-tear associated with traditional rotary torque sensors, making the RTT12 maintenance-free and highly durable. By providing real-time torque feedback, it enhances precision in robotic motion control, enabling smoother operations, reduced mechanical stress, and improved safety in collaborative robotics. The RTT12 excels in applications demanding consistent torque monitoring. In robotics, it optimizes joint performance by delivering instant feedback for adaptive control algorithms. It is equally vital in torsional testing machines, where it evaluates material durability under cyclic loads, and in actuator validation, ensuring motors maintain specified torque outputs across varying conditions. Industrial process control systems also benefit from its ability to safeguard product quality through continuous torque surveillance in assembly lines or precision machining.

For specialized needs, the Stationary Torque Transducer RTT12 offers customization options, including tailored dimensions, connectors, or signal outputs, making it ideal for OEM integration or niche applications. Its compatibility with harsh environments, combined with plug-and-play installation, ensures minimal downtime and maximum ROI. By merging rugged stainless steel construction with advanced sensing technology, the RTT12 torque meter bridges the gap between reliability and innovation. Whether deployed in agile robotic arms, actuators, or automated manufacturing lines, this sensor empowers industries to achieve unparalleled control, efficiency, and accuracy in torque-critical tasks—proving that compact design and high performance can coexist seamlessly.