sales@loadcellsensor.com

sales@loadcellsensor.com

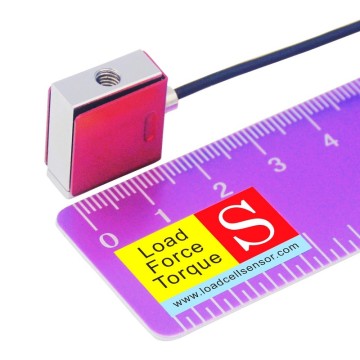

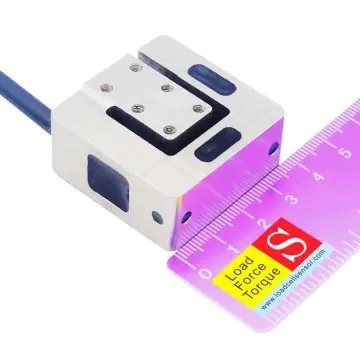

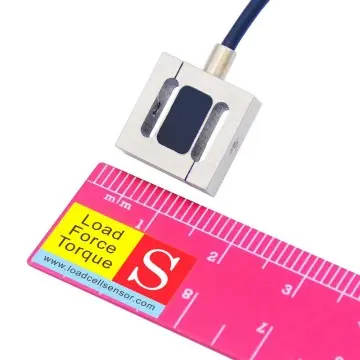

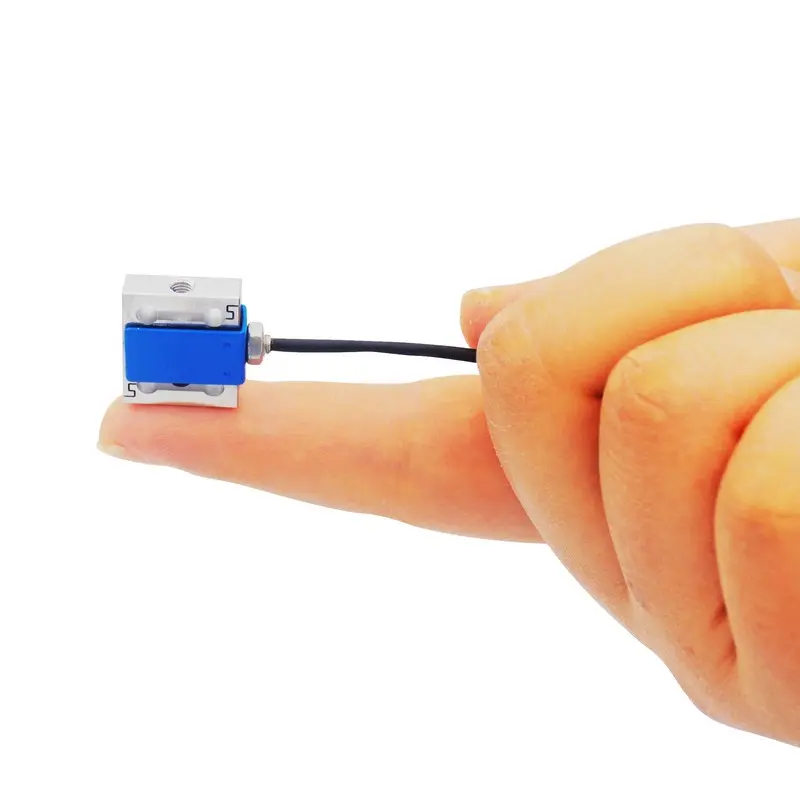

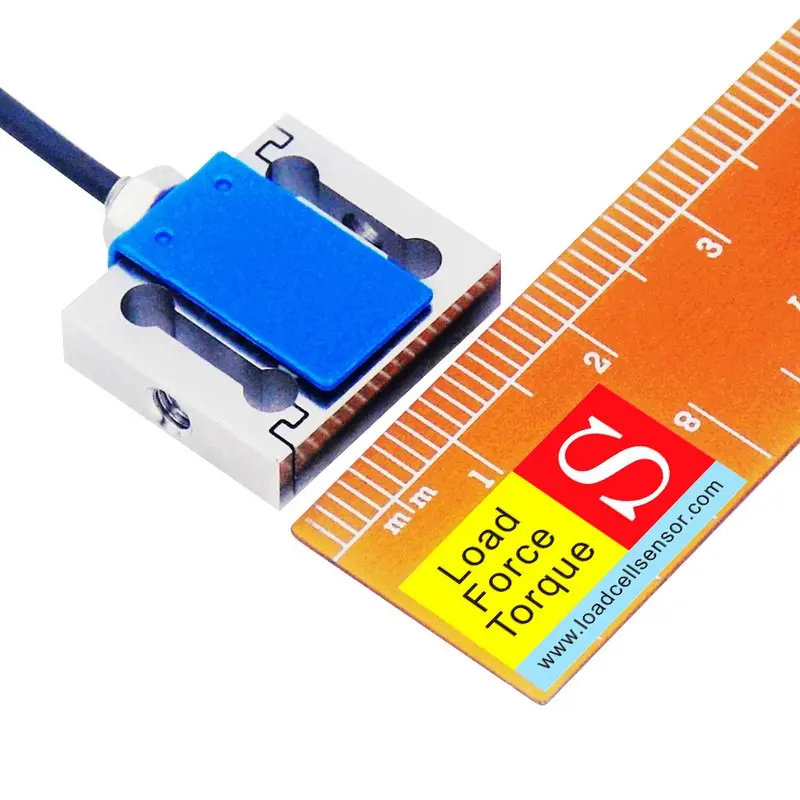

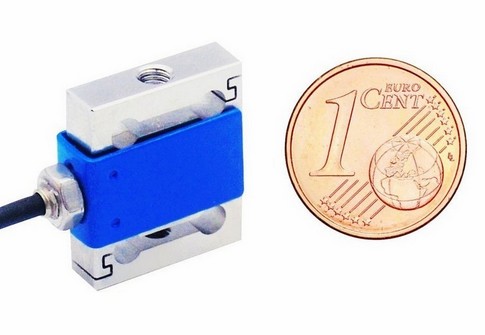

Micro Force Sensing Sensor 1N 2.5N Push Pull Load Cell

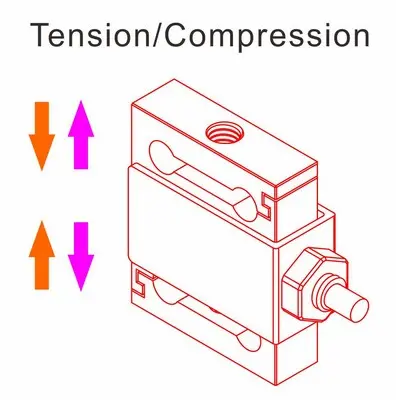

The LCSM Micro Force Sensor is a cutting-edge, bidirectional force measurement solution designed to deliver laboratory-grade accuracy in both tension (pull) and compression (push) applications. Combining ultra-compact dimensions with industrial durability, this sensor is engineered for industries where space constraints, precision, and reliability are non-negotiable.

The M3 tapped holes on both ends of LCSM enable effortless attachment of threaded rods, eye bolts, load buttons, or custom fixtures, ensuring adaptability across diverse setups. Whether integrated into portable devices, robotic systems, or precision assembly lines, the LCSM's modular design simplifies installation while maintaining alignment for accurate axial force measurement.

At the heart of the LCSM lies strain gauge technology, providing a resolution of 0.0003N/0.00075N and a maximum non-linearity of 0.2% of full scale. This exceptional sensitivity allows the sensor to detect minute force variations, critical for applications like micro-mechanical testing or medical device calibration. Each unit undergoes rigorous pre-shipment testing, including load cycling and temperature stability checks, to ensure compliance with stringent quality standards.

With a miniature footprint and lightweight construction, the LCSM is ideal for space-constrained environments. Its S-beam design minimizes off-axis loading errors, while the stainless steel body ensures long-term stability under repetitive use. The sensor's bidirectional capability eliminates the need for multiple devices, streamlining workflows in dynamic applications such as robotic gripping or automated quality control.

Industry-specific applications:

-

Spring Testing: Validates compression/tension forces in precision springs for automotive or aerospace components.

-

Textile Manufacturing: Monitors fabric tension during weaving or stitching to prevent defects and ensure consistency.

-

Robotics: Enhances collaborative robot (cobot) safety by providing real-time force feedback for adaptive gripping.

-

Medical Devices: Integrates into surgical instruments or prosthetics to measure tactile feedback, improving patient outcomes.

-

Precision Assembly: Ensures accurate force application in microelectronics, watchmaking, or semiconductor production.

Every LCSM force sensing sensor is subjected to comprehensive inspection, including zero-balance calibration and signal linearity tests, to guarantee out-of-the-box readiness. The shielded cable (included) reduces electromagnetic interference, ensuring clean signal transmission even in electrically noisy industrial settings. While the LCSM excels as a standard solution, customization options are available for specialized tasks. Tailored thread sizes (e.g., M2 or M4), or environmental protections can be developed to meet niche requirements. OEM partnerships benefit from scalable production runs, ensuring cost-efficiency without sacrificing precision.

The LCSM Micro Force Sensing Load Cell redefines precision in compact force measurement, bridging the gap between laboratory accuracy and industrial practicality. Its ability to thrive in medical, robotic, and manufacturing environments makes it indispensable for engineers seeking reliable, high-resolution data. By combining ruggedness with micro-scale sensitivity, the LCSM empowers industries to innovate confidently, ensuring quality and efficiency in every force-critical application.