sales@loadcellsensor.com

sales@loadcellsensor.com

Multi-axis Load Cell 100kg 50kg 20kg 10kg 5kg Triaxial Load Cell

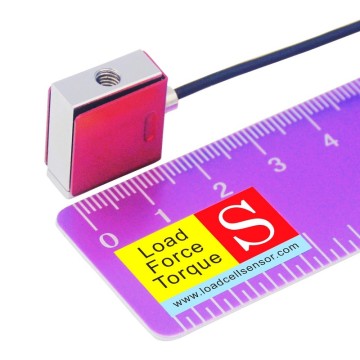

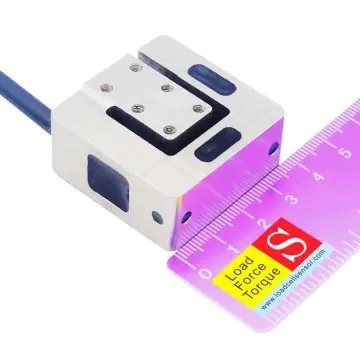

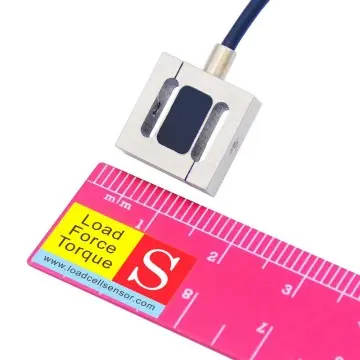

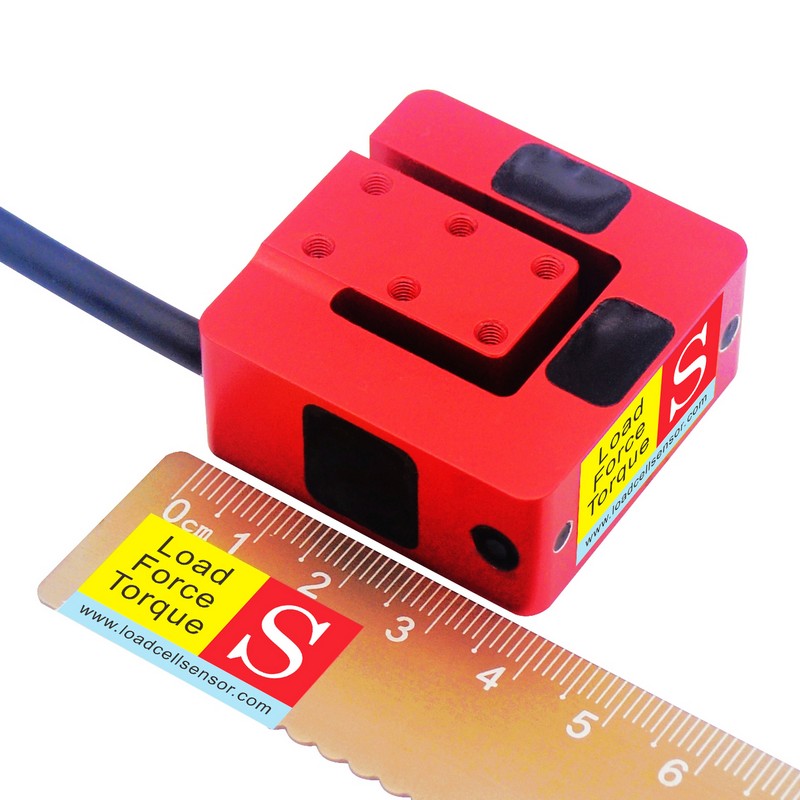

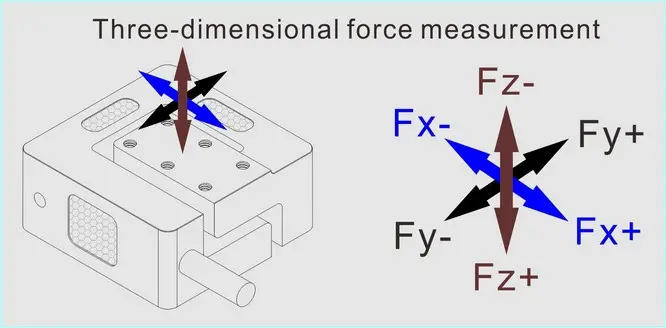

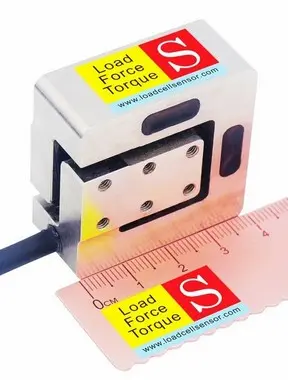

The LCM09 multi-axis load cell stands out in the field of precision force measurement due to its exceptionally compact design. With a footprint of just 40x40mm and a height of only 20mm, this miniature sensor is purpose-built for applications where space is limited but high-resolution, three-dimensional force monitoring is critical. Its small form factor, combined with robust performance, makes it a preferred choice across industries that demand accuracy and flexibility in tight installation environments.

Available in capacities of 5kg, 10kg, 20kg, 50kg, and 100kg, the LCM09 can be manufactured from either aluminum or stainless steel, depending on the required strength, environmental exposure, and force range. This material flexibility allows it to meet a wide range of industrial standards and customer-specific needs, whether the focus is on weight reduction or corrosion resistance.

Designed for 3-axis force sensing, the LCM09 provides precise, simultaneous measurement of force in the Fx, Fy, and Fz directions. Unlike systems that require complex vector calculations to interpret data, the LCM09 outputs direct force values from each axis, simplifying both integration and data analysis. Each axis includes a 1000-ohm Wheatstone full bridge circuit, which enhances measurement stability and significantly reduces power consumption compared to conventional 350-ohm bridges. This makes the sensor ideal for battery-powered or portable systems, where energy efficiency is paramount.

The load cell is also capable of measuring forces in both tension and compression. It generates a positive output for compression and a negative output for tension (or vice versa, depending on installation). This bidirectional capability ensures broad usability across various mechanical testing setups, making it a highly versatile tool.

Typical Applications of the LCM09 Multi-Axis Load Cell:

1. Anti-Collision Detection in Automation

In industrial automation and robotics, collision avoidance is crucial for protecting equipment and improving worker safety. The LCM09 multi-axis sensor can be integrated into robotic arms or automated machinery to detect unexpected force in any direction, helping prevent accidents and reducing downtime. Its compact size allows for easy integration into moving parts where space is at a premium.

2. Rehabilitation Robotics

In the medical and healthcare sector, particularly in robot-assisted rehabilitation, monitoring patient interaction forces is essential. The LCM09 3D load cell can be embedded in exoskeletons or therapy robots to measure the multi-directional forces exerted by or on the patient, ensuring safe and effective recovery. Its high sensitivity and stability help clinicians assess progress and tailor therapy sessions.

3. Automotive Component Testing

The automotive industry uses multi-axis sensors like the LCM09 to evaluate the durability and performance of parts under real-world forces. For example, during suspension testing, this sensor can accurately capture forces from multiple directions simultaneously, offering engineers valuable insights for improving design and safety standards.

4. Medical Research and Device Development

The LCM09 is invaluable in biomedical research, where precise measurement of human or mechanical interaction forces is needed. It's frequently used in the development and testing of prosthetics, surgical tools, and diagnostic equipment. Its high resolution and minimal footprint make it especially well-suited for integrating into delicate instruments without affecting their operation.

In conclusion, the LCM09 tri-axial force sensor combines compact design, robust construction, and efficient electronics to deliver reliable and precise multi-directional force measurement. Whether it's enhancing automation safety, advancing medical technology, or refining automotive performance, this load cell proves to be a highly adaptable and effective solution. For non-standard needs, customization services are available, ensuring the LCM09 can meet the most unique and challenging application requirements.