sales@loadcellsensor.com

sales@loadcellsensor.com How to Choose the Right Load Cell Force Sensor for Your Application

As industrial automation continues to advance, the demand for reliable and accurate force measurement has grown across a wide range of industries, including manufacturing, robotics, medical devices, automotive, and aerospace. Load cell Force Sensors play a critical role in this space, enabling precise monitoring and control of mechanical forces. However, with so many types, capacities, and specifications available, selecting the right load cell for your application is not always straightforward. A careful evaluation of your system requirements is essential to ensure proper function, safety, cost-efficiency, and long-term reliability.

Here are several key factors to consider when selecting the most suitable load cell for your application:

- Load Capacity: Leave Room for Safety

One of the most fundamental factors in selecting a load cell is determining the appropriate load capacity. Overloading is a leading cause of sensor failure, often resulting in permanent damage or reduced accuracy. To avoid this, always select a sensor with a capacity that exceeds the maximum load expected in your application. A common guideline is to choose a sensor rated for 120–150% of the anticipated full load, which provides a safety buffer against unintentional overloads. For example, if your maximum force is 1000N, consider a load cell rated for at least 1200N to 1500N, 2000N rating can also be an option.

- Measurement Type: Compression, Tension, or Both?

Understanding the type of force you need to measure is equally important. Some applications require measurement of compressive force only (such as press-fit operations), while others involve tensile forces (such as pull tests), or even both. Fortunately, many modern load cells—particularly S-type and shear beam designs—can support bi-directional force measurement. Confirm the measurement direction(s) required in your setup to ensure compatibility.

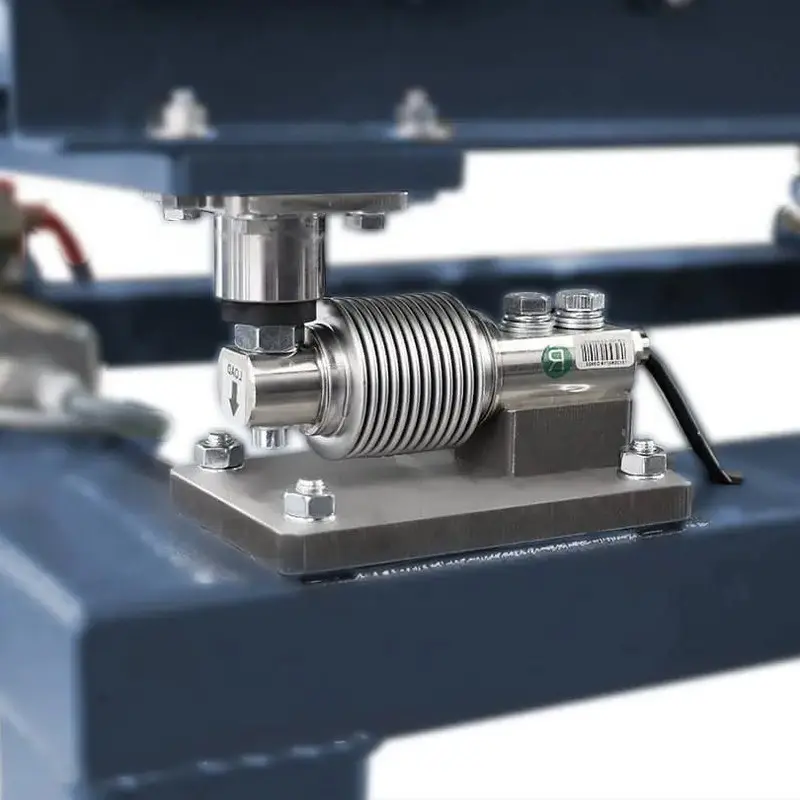

- Sensor Type: Match Form to Function

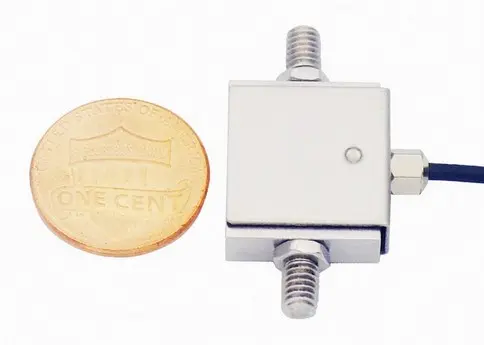

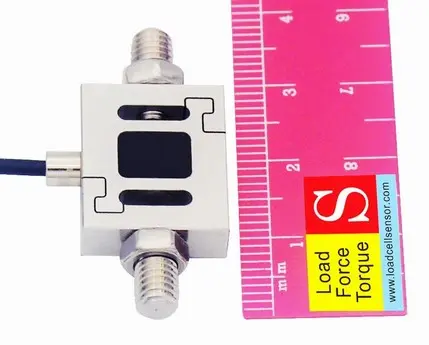

Load cells come in many shapes and structures, each suited to specific mechanical configurations. Button Load Cells are compact and ideal for limited spaces, while S-beam sensors are excellent for suspended or tension applications. Shear beam and pancake load cells are typically used in platform or structural testing. For bench scales or packaging machines, a single-point sensor is a good choice due to its ability to handle off-center loading. Your selection should consider both the mechanical installation method and how the load is applied.

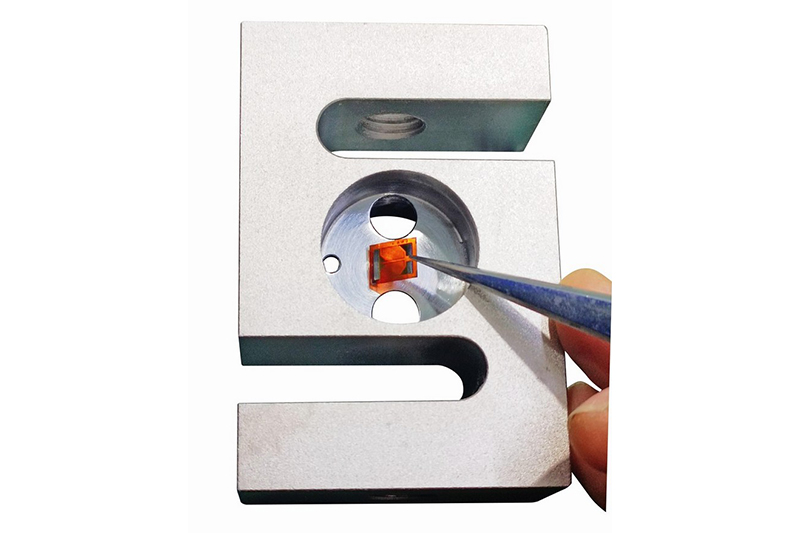

- Accuracy Requirements: Precision vs. Practicality

The accuracy class of the sensor—defined by parameters like resolution, linearity, hysteresis, and repeatability—will depend on your application. In high-precision applications like material testing or analytical weighing, a sensor with low non-linearity and minimal hysteresis is critical. On the other hand, in industrial process control where only general monitoring is needed, a more affordable, lower-accuracy sensor may suffice. Evaluate the tolerance for measurement error in your process and choose accordingly.

- Environmental Conditions: Consider the Surroundings

Force sensors can be sensitive to external environmental factors, including temperature extremes, moisture, dust, vibration, and corrosive chemicals. For outdoor or harsh environments, it is advisable to select sensors that are IP-rated for water and dust resistance, or even explosion-proof if used in hazardous zones. Temperature compensation is another important feature for applications exposed to significant thermal variations.

- Size, Mounting, and Mechanical Integration

Every application has space and mounting constraints, and these should be matched to the physical characteristics of the load cell. Dimensions, mounting holes, cable orientation, and load direction must all be reviewed to ensure seamless integration into your mechanical system. Where possible, opt for load cells that minimize required modifications to your existing setup.

- Signal Output: Speak the Same Language

Load cells output analog or digital signals that must be compatible with your data acquisition system. The most common signal format is mV/V, which typically requires amplification. Alternatively, amplified versions with 0-5V, 0-10V, 4-20mA, or digital outputs (RS485, RS232, Modbus) are also available. Consider your available electronics and decide whether a built-in amplifier or external signal conditioner is needed.

- Overload Protection: Built-in Safety

In applications where sudden or unpredictable forces may occur, mechanical overload protection is a valuable feature. Some load cells are equipped with internal stops or protective mechanisms that prevent the strain gauge from being damaged. This can significantly extend the life of the sensor, especially in dynamic or impact-prone environments.

- Static vs. Dynamic Measurement

Another critical consideration is whether your application involves static or dynamic force measurement. This affects both the sensor material and internal structure. Stainless steel load cells typically offer superior performance for dynamic measurements due to their strength and responsiveness. Additionally, the internal structure—such as the location of strain gauges and damping mechanisms—can influence the sensor's response time and accuracy under rapidly changing loads.

- Material and Durability: Built to Last

Material selection plays a role in both durability and cost. Stainless steel is highly resistant to corrosion and suitable for demanding environments. Aluminum load cells are lighter and cost-effective but may not be as robust. Depending on your industry, one may be preferable over the other.

- Budget and Lead Time: Balance Cost and Availability

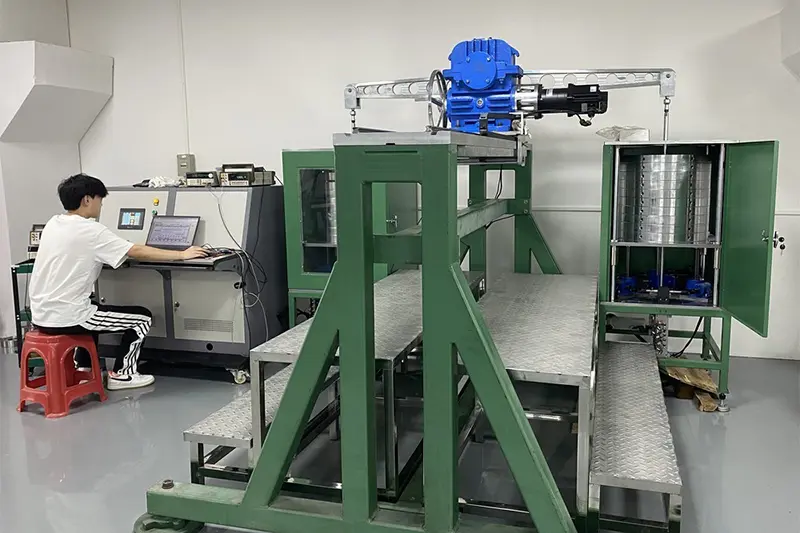

While technical performance is crucial, budget constraints and delivery timelines cannot be overlooked. Standard models may be in stock and can ship quickly at lower cost. However, custom-designed or specialized sensors often involve longer lead times (typically 3–5 weeks) and higher prices. When time is critical, check for available inventory before committing to a custom model.

- Customization for Seamless Integration

In applications where the mechanical layout cannot be changed, a custom load cell is often the best solution. Tailoring the mounting dimensions, output signal, cable length, or even the sensor's sensitivity ensures compatibility with existing systems and minimizes the need for design changes. LCS Tech Co., Limited offers OEM customization services to help customers achieve a seamless fit.

Choosing the right load cell force sensor involves more than just picking a model off the shelf. It requires a thorough understanding of your application's force direction, mechanical layout, accuracy demands, environment, and system integration. By carefully evaluating each of these factors and working with a knowledgeable supplier, you can ensure a reliable, long-lasting, and cost-effective solution for your force measurement needs.