sales@loadcellsensor.com

sales@loadcellsensor.com

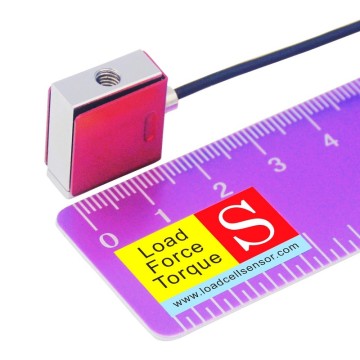

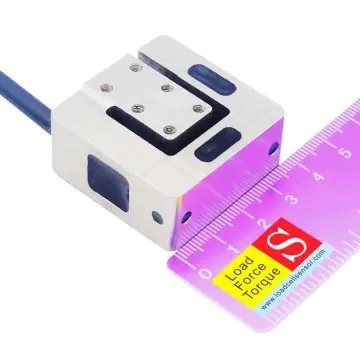

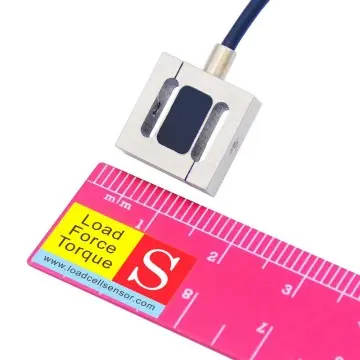

0-2kN Roll Load Cell For Web Tension Control

The STAG Roll Load Cell, developed by LCS, is a precision-engineered flange load cell designed to ensure optimal tension control in various continuous material processing systems. Installed at both ends of a roller, the STAG sensor provides real-time detection and feedback of web tension, allowing operators to monitor and adjust tension levels continuously. This ensures the stable and efficient operation of machinery, especially in industries where uniform material tension is essential for maintaining quality and preventing process disruptions.

At the heart of the STAG sensor's design is a NSK 2203 bearing, making it compatible with shafts that have a 17mm diameter. The load cell is available in four rated capacities—0.3kN, 0.5kN, 1kN, and 2kN—to accommodate a range of application requirements. Each sensor is delivered with a calibrated and consistent rated output, simplifying integration with signal processing systems and reducing the time required for system setup and calibration.

In many production processes, maintaining a consistent web tension is crucial. Industries such as printing, packaging, textile, and paper manufacturing rely heavily on this balance. Low tension can cause the material to sag or misalign, disrupting the guiding system. On the other hand, excessive tension can stretch or even tear the material, leading to defects in printing or cutting, as well as costly machine downtime. The STAG tension sensor plays a critical role in avoiding such issues by providing accurate and reliable tension measurements.

By integrating the STAG sensor into their equipment, manufacturers can enhance quality control, minimize waste, and maximize productivity. Here are typical applications where the STAG tension measurement sensor demonstrates its value:

- Paper Manufacturing

In paper production lines, maintaining consistent tension is vital to avoid wrinkling or tearing of paper rolls. The STAG tension control sensor ensures smooth winding and unwinding, reducing material loss and machine stoppages. - Printing Presses

Accurate tension control is essential for high-quality print results. Model STAG helps prevent image distortion and misalignment caused by uneven material feed, resulting in sharper, more reliable prints. - Textile Weaving

Textile production requires consistent tension to avoid fabric deformation and ensure even weaving. The STAG sensor supports seamless fabric handling and helps maintain fabric integrity. - Plastic Film Production

Thin films are highly sensitive to tension variations. The STAG sensor prevents stretching or tearing during extrusion and rolling, ensuring uniform thickness and consistent product quality. - Metal Foil Processing

Metal foils such as aluminum or copper are delicate and prone to damage under tension variations. STAG sensors help maintain optimal tension, preventing creases or material breakage during high-speed processing. - Label and Adhesive Tape Production

In applications where materials must be precisely cut and aligned, such as label and tape manufacturing, tension consistency is essential. The STAG sensor ensures accurate material handling and product uniformity. - Battery Electrode Coating

In battery production, the coating of electrodes must be done under tightly controlled tension to ensure uniform thickness and proper adhesion. STAG sensors contribute to high-precision coating processes. - Cable and Wire Manufacturing

In the production of cables and wires, maintaining even tension ensures smooth insulation application and winding. The STAG tension load cell helps maintain dimensional consistency and prevents material damage. - Hot Rolling Mills

For steel or other metals processed in rolling mills, accurate tension measurement is essential for shaping and handling. The STAG tension sensor helps optimize rolling processes and reduce scrap material.

Whether it's winding, unwinding, coating, cutting, or printing, the STAG flange load cell from LCS offers a robust and reliable solution to tension-related challenges. Additionally, LCS provides customization services to accommodate unique or complex measuring requirements, ensuring a perfect fit for your specific application. Incorporating STAG tension sensors into your production line not only safeguards product quality but also enhances operational efficiency and reduces downtime—key factors for maintaining competitiveness in today's fast-paced industrial landscape.