sales@loadcellsensor.com

sales@loadcellsensor.com

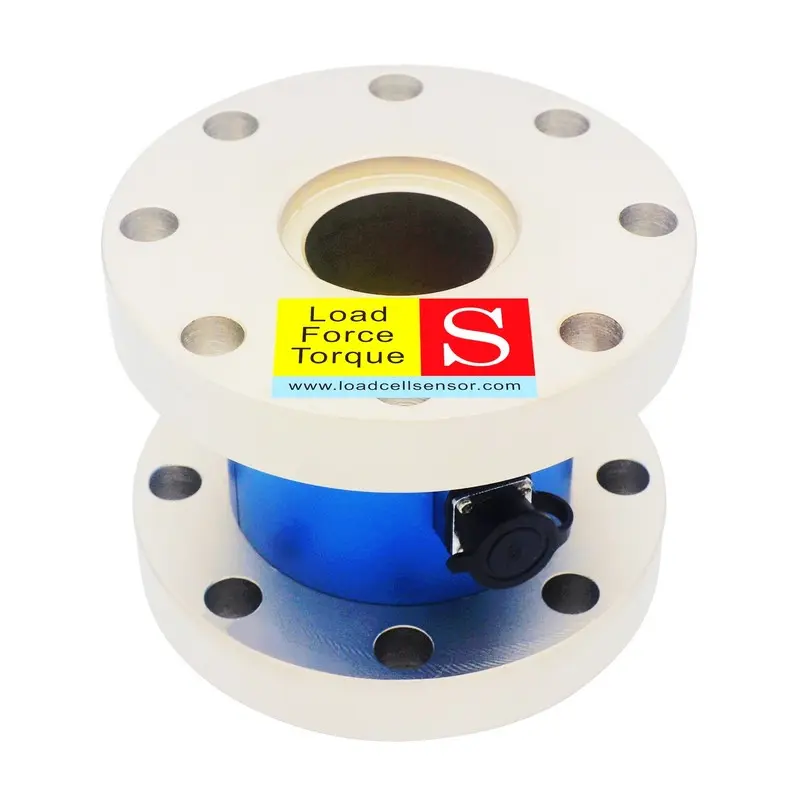

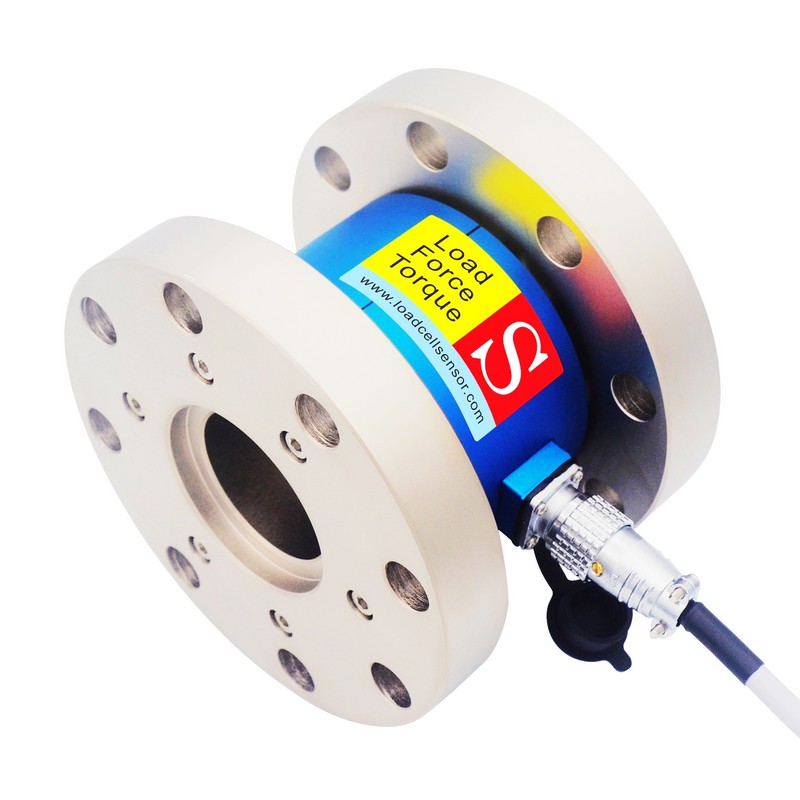

Thru-hole flange to flange reaction torque cell 0-10kNm

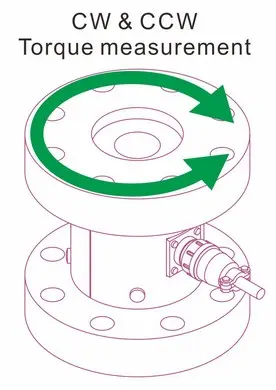

The RTT07 Flange-to-flange Reaction Torque Sensor is a high-precision reaction-type transducer designed to accurately measure torque in both clockwise and counterclockwise directions. Engineered with advanced metal foil strain gauges, which are bonded to a specially machined portion of the sensor's elastic body, the RTT07 ensures exceptional performance. It delivers high measurement accuracy with a maximum non-linearity of just 0.25%, offering precise results across a wide range of torque values, from 200Nm to 10kNm. This broad range makes it a versatile tool, ideal for a variety of industrial applications where reliable torque measurement is essential.

The stationary design of the RTT07 hollow torque sensor ensures that it remains secure within a system, providing excellent durability and resistance to mechanical stress. Whether for routine monitoring or high-precision testing, the RTT07 delivers consistent, dependable performance.

Typical applications of the RTT07 static torque cell:

- Motor Torque Measurement: The RTT07 is often used for measuring the torque produced by motors in a wide range of systems, from industrial machinery to electric vehicles. Accurate torque measurement allows for efficient motor performance monitoring and ensures that motors operate within optimal conditions, avoiding potential damage or inefficiencies.

- Test Bench Applications: In test benches, the RTT07 torque sensor is utilized to assess the torque output of different machines, components, or devices under test. These applications require accurate and real-time feedback, and the RTT07 provides the necessary precision to optimize test protocols.

- Screwdriver Calibration: For applications involving power tools such as electric screwdrivers, the RTT07 can measure the torque applied during fastening or unscrewing tasks. This ensures that tools are calibrated correctly for consistent, reliable performance and that they meet the required torque standards for specific jobs.

- Fatigue Testing: The RTT07 torque load cell is also useful in fatigue testing, where components or materials are subjected to repetitive torque or stress over time. This helps determine the long-term durability of materials under torque-related stress, which is crucial for quality control and safety testing in industries like aerospace, automotive, and construction.

- Actuator Testing: The sensor is employed in the testing of actuators—devices that convert electrical energy into mechanical motion. By measuring the torque generated during testing, engineers can ensure that actuators meet the required specifications for efficiency and performance, vital in systems such as robotic arms or automotive drive systems.

For more specific measurement needs, LCS Tech Co., Limited offers the option to customize the RTT07 torque transducer to meet particular application requirements. Whether you need a model with a different torque range, altered dimensions, or other specifications, the RTT07 can be tailored to deliver optimal results. This makes the RTT07 not only a reliable tool for standard applications but also an ideal choice for industries with specialized measurement demands. By choosing the RTT07 flange-to-flange torque meter, industries benefit from an accurate, robust, and cost-effective solution for their torque and thrust measurement tasks. With its broad measurement range, precise performance, and versatile applications, the RTT07 is engineered to handle the most challenging industrial environments.