sales@loadcellsensor.com

sales@loadcellsensor.com

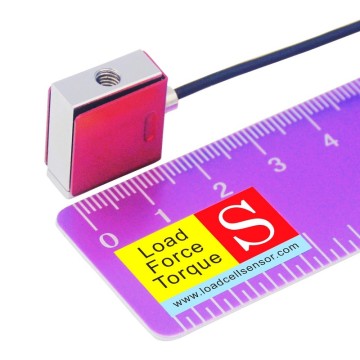

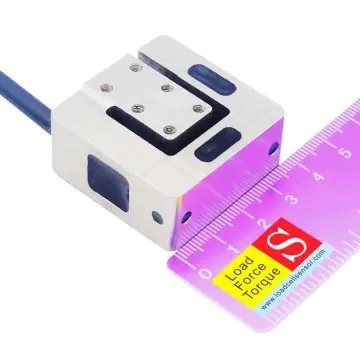

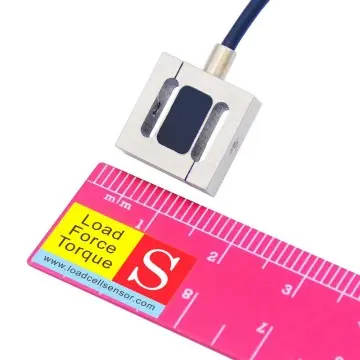

M8/M10/M12 Tapped Tension Compression Load Cell 0-500kg

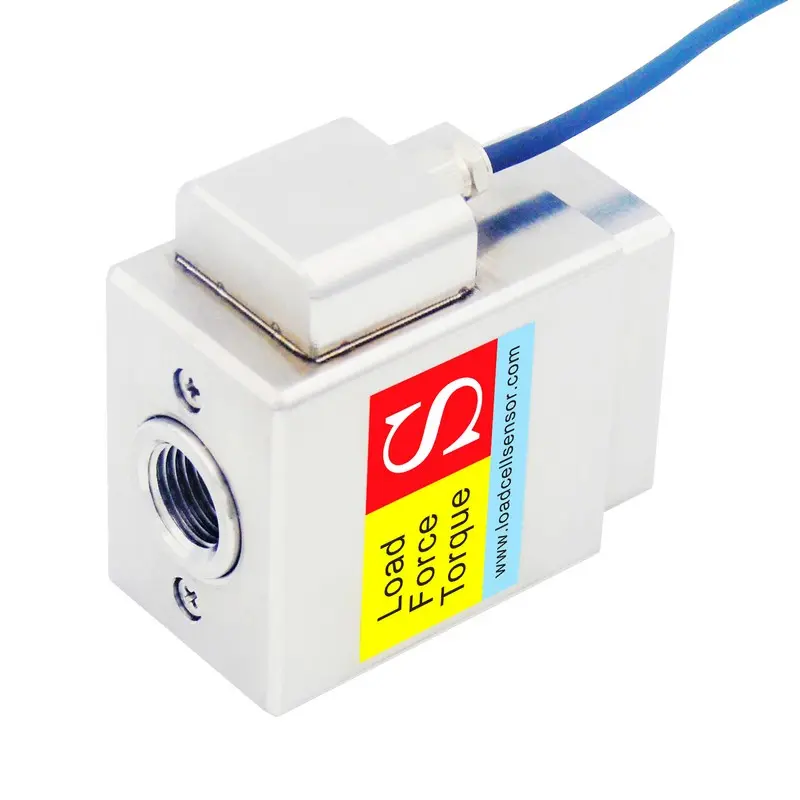

The SLC02 tension compression load cell is a high-precision force measurement sensor specifically engineered for accurate and stable bidirectional force measurement in both tension and compression modes. Constructed from high-grade stainless steel, the SLC02 ensures excellent resistance to corrosion, mechanical fatigue, and environmental influences, making it an ideal choice for long-term industrial and research applications. With rated capacities available in 50kg, 100kg, 200kg, 300kg, and 500kg, this robust load cell provides dependable performance across a broad range of measurement tasks—from laboratory testing to automated production lines and structural evaluation.

Designed with versatility in mind, the SLC02 tension compression load cell supports multiple mounting configurations through M8, M10, and M12 threaded holes, offering flexibility for diverse installation scenarios. To accommodate different application needs, the sensor can be fitted with optional accessories such as load buttons, eye bolts, and threaded rods, enabling precise alignment and easy adaptation to various force transmission methods. Unlike conventional load cells with radial cable exits, the SLC02 features a unique axial cable outlet, which minimizes radial space requirements and prevents cable fatigue caused by bending. This compact and efficient design allows seamless integration into systems with limited side clearance, such as compact machinery or testing fixtures.

For customized applications that demand specific mechanical dimensions, connector types, or signal outputs, LCS Tech Co., Limited provides tailored design and manufacturing services based on the SLC02 platform. This makes it possible to optimize the sensor’s configuration for specialized force measurement scenarios, ensuring both high accuracy and structural robustness.

Below are seven detailed application examples where the SLC02 force detection sensor demonstrates exceptional performance and reliability:

- Press-fit force monitoring in automated assembly – Ensures precise control during insertion processes, preventing component damage and improving assembly consistency.

- Spring or actuator load calibration – Provides accurate verification of spring constants and actuator output forces, essential for mechanical quality control.

- Structural load analysis in small mechanical components – Used to evaluate stress distribution and verify load-bearing performance in miniature mechanical parts.

- Calibration of testing machines or instruments – Serves as a reference standard for validating the accuracy of material testing and force measurement equipment.

- Force analysis in medical research equipment – Ideal for measuring precise biomechanical loads in rehabilitation devices, surgical simulators, or prosthetic testing.

- Sensor integration for academic experiments – Frequently adopted in universities and R&D institutions for force measurement experiments, robotics studies, and mechanical dynamics research.

- Load monitoring in automated welding or riveting systems – Ensures optimal joining force and process consistency, improving the quality and durability of manufactured assemblies.

With its durable structure, flexible mounting, and high measurement fidelity, the SLC02 force sensing load cell is a trusted and adaptable solution for engineers, researchers, and manufacturers who demand precision and reliability in both static and dynamic force measurement applications.