sales@loadcellsensor.com

sales@loadcellsensor.com

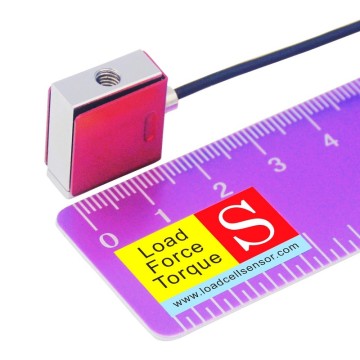

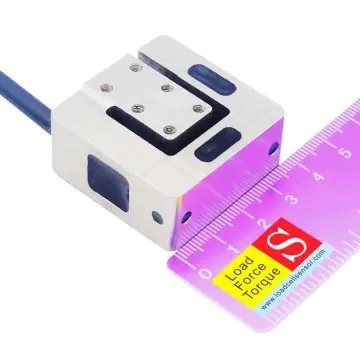

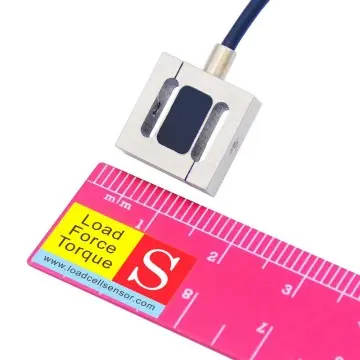

Weight Measurement Sensor 20kg 10kg 5kg 3kg Single Point Load Cell

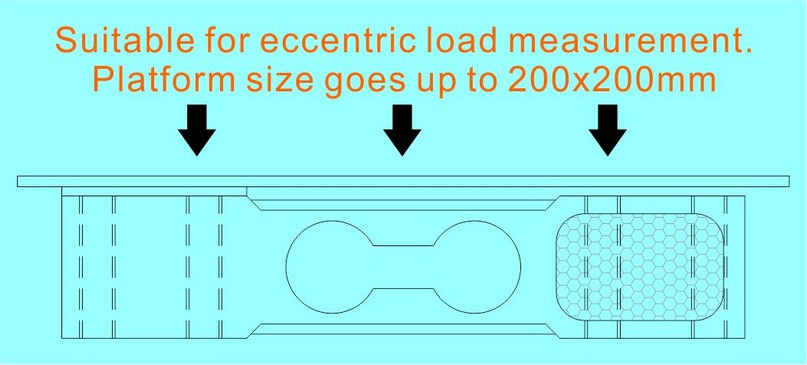

The LCE15 Weight Cell Sensor is a compact, high-precision single point load cell designed for accurate off-center load measurement, making it ideal for compact and automated weighing systems. With its advanced corner trimming calibration, the LCE15 delivers stable and consistent readings regardless of where the weight is applied on a platform of up to 200x200mm. This capability is especially useful in dynamic applications where perfect load placement cannot be guaranteed.

Constructed from lightweight aluminum and built on a Wheatstone full-bridge strain gauge configuration, the LCE15 weighing machine sensor is engineered for long-term stability and sensitivity. It features a 1000-ohm high-resistance design, which reduces power consumption significantly when compared to traditional 350-ohm load cells. This makes it ideal for battery-powered or energy-efficient systems where minimizing power draw is essential.

The LCE15 offers rated capacities of 3kg, 5kg, 10kg, 15kg, and 20kg, with a sensitivity of 2.0mV/V, ensuring reliable performance across a broad range of low-force weighing needs. The sensor is also temperature compensated, maintaining accuracy across various operating conditions, which is critical for environments with fluctuating ambient temperatures.

With its small footprint, high accuracy, and affordable cost, the LCE15 beam type load cell provides a perfect balance of performance and value. It is widely used in OEM system integration, where precision, reliability, and easy installation are priorities. Its compatibility with a variety of digital and analog amplification systems ensures smooth integration into diverse industrial automation setups. Typical applications include:

- Weight Sorting Systems: Used in automated packaging and manufacturing lines to sort products by weight, ensuring consistent output and eliminating underweight or overweight items.

- Smart Vending Machines: Monitors the real-time weight of products to confirm accurate dispensing and detect product availability, improving user experience and system reliability.

- Gravimetric Feeders: Enables precise material dosing based on weight in processes like plastic extrusion, food mixing, or chemical blending.

- Food Packaging Lines: Ensures each package receives the correct quantity of product by verifying fill weights, improving consistency and reducing waste.

- Ingredient Batching Systems: Used in recipe-based automation to weigh and batch ingredients, whether in food production or chemical formulation.

- Multi-Head Weighers: Plays a vital role in parallel weighing systems, ensuring each weighing head produces synchronized and accurate output for high-speed packaging.

- Automatic Filling Lines: Controls product flow in automated filling systems, ensuring target weight is achieved before sealing or packaging.

- Checkweighers: Acts as a key sensor in in-line inspection systems to verify product weight and reject defective items from the production line.

In conclusion, the LCE15 Weight Measurement Sensor combines compact size, energy efficiency, and high precision, making it a top choice for modern, automated weight measurement tasks. Its reliability and flexibility make it indispensable for OEMs, system builders, and manufacturers seeking to implement accurate and efficient weighing solutions in a wide range of industries.